Final Drive Rebuilt for CJ750 / M72 - Gear Contact Pattern

24 April, 2023

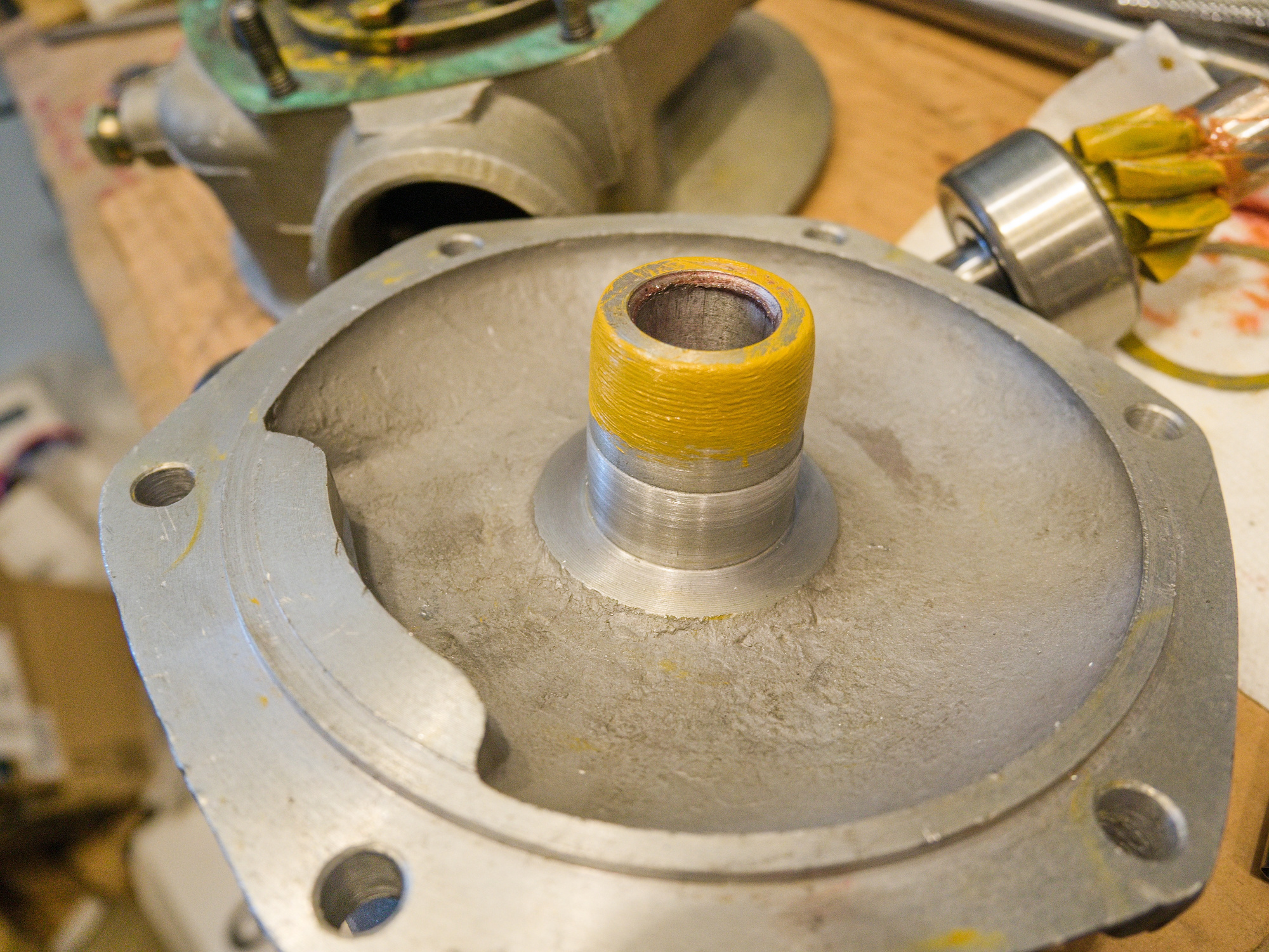

The distance from the ring gear to the pinion gear is set by shims between the cover and the bearing. Often the hub with the bearing is pressed on to the cover, making adjustments with different shims difficult.

For this reason, the tubular holder in the cover is made for a perfect fit without the need for a press. Very careful sanding with a fine grid paper will get a transition fit.

The pinion gear will always push out the ring gear towards the cover. Along with the o-ring in the drive shaft, additional push is provided to keep everything in place.

The gear compound at the top of the shaft is to check for any contact with the hub. Often a common source for noise.

The 1-3/8"x1-7/8" Arbor Shims are used to space the ring gear. The M52x42x0.2 shims are used to space the pinion gear. The M52 shims were sold in a pack of 125 only.

To make the pinion adjustment easier, a plastic replacement for the bearing with a undersize is used to allow quickly sliding the pinion gear in and out.

Gear compound is used to see the contact pattern.

The contact pattern gets visible once the gear is rotated. Apply some pressure to the ring gear when rotating the pinion gear to get a clear pattern.

Rotate forth and back to get a pattern for the cruise and drive side.

This is the drive side. Needs adjustment.

This is the cruise side. Also not acceptable. The distinctive bottom line must not appear. The pattern should be uniform and gradually fade out.

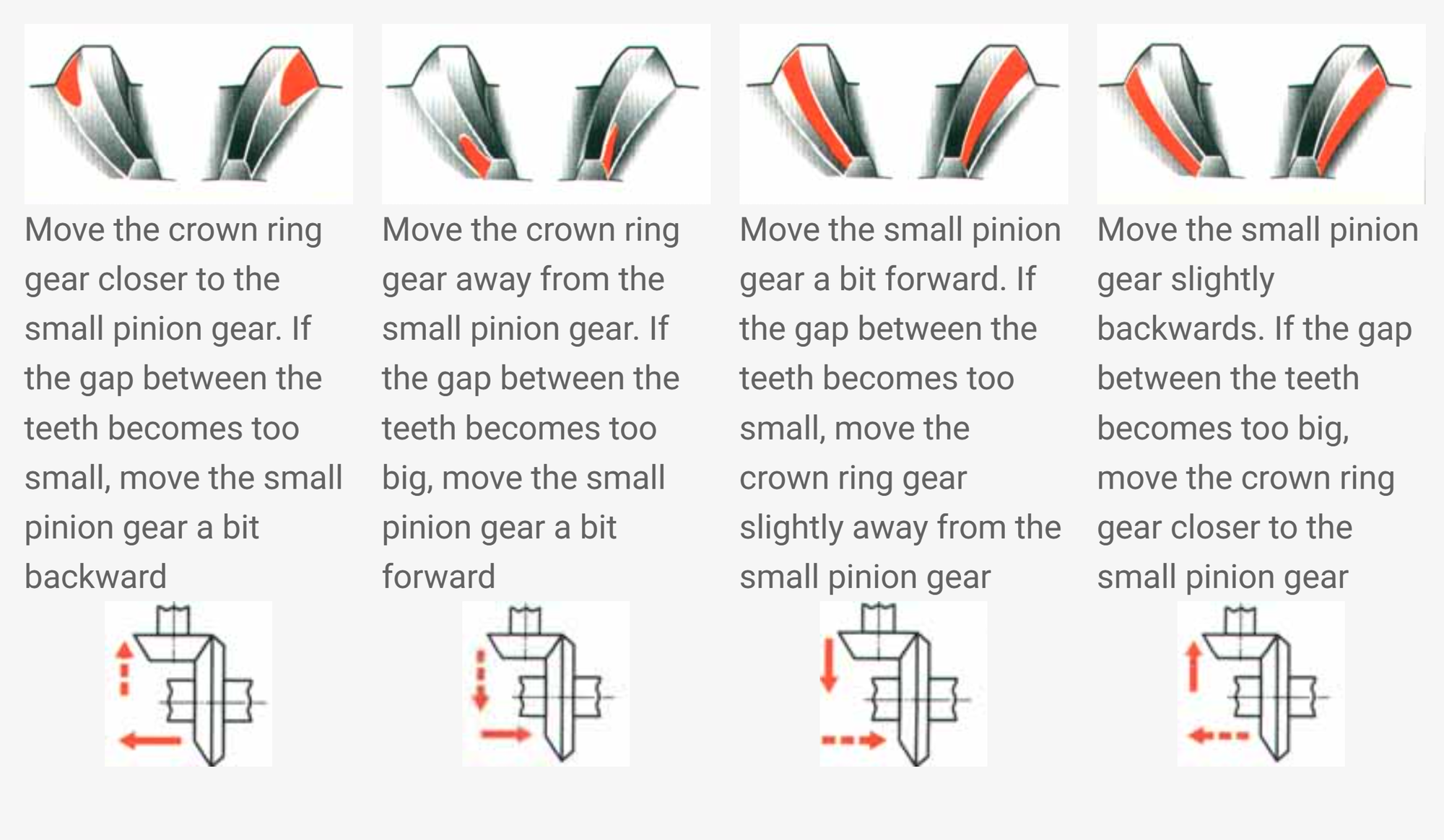

Guide to adjust the contact pattern.

Search for contact pattern to get more detailled guides on how to adjust the gears.

Using the contact pattern guides, move the ring gear by adding or removing 1-3/8"x1-7/8" Arbor shims between the cover and the hub bearing, and move the pinion gear by adding or removing M52x42x0.2 shims between the housing and the bearing.

Acceptable contact pattern for the drive side.