CJ750 Gearbox gets a new 3rd and 4th gear - Modify the input shaft

05 October, 2024

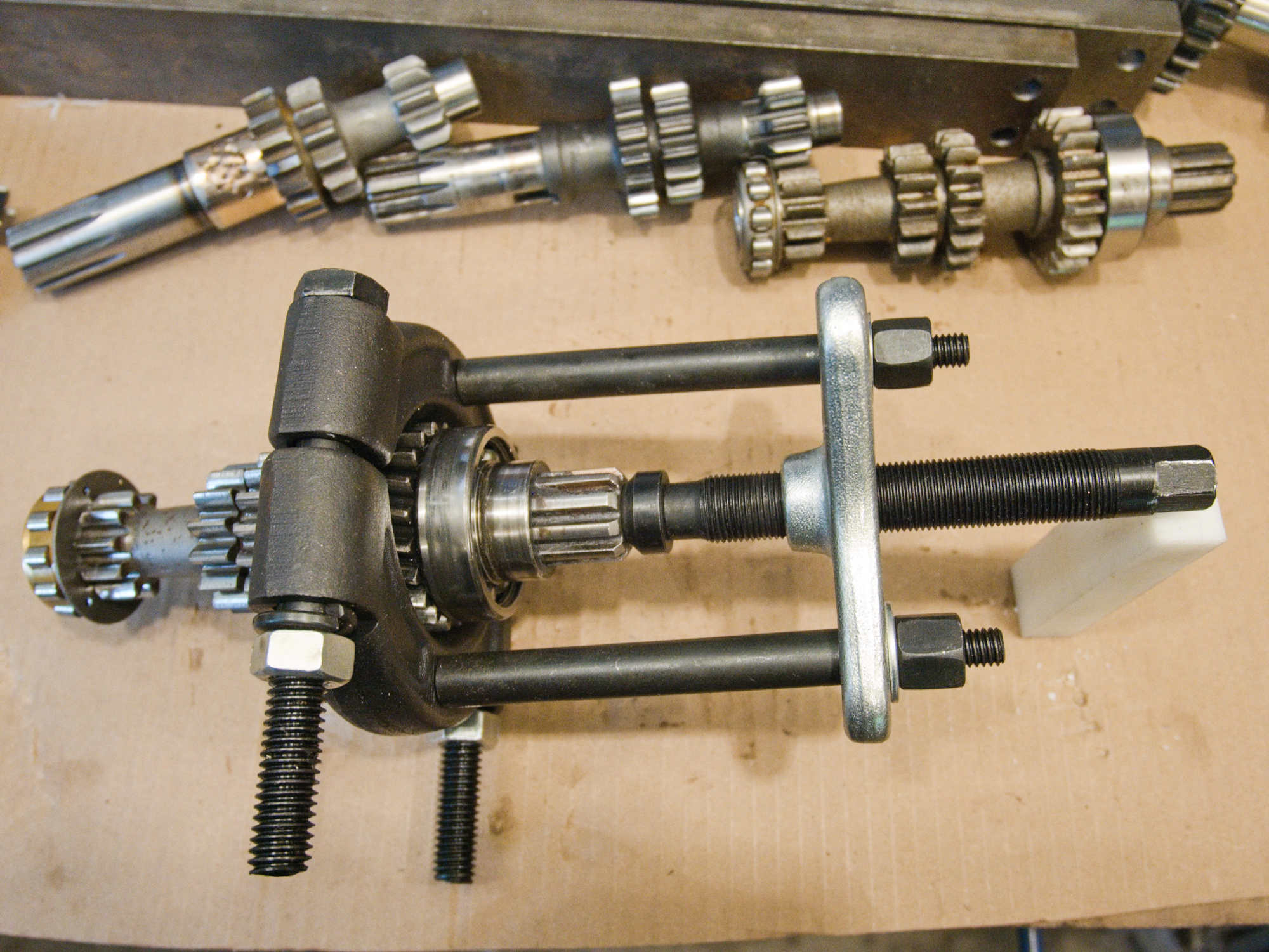

To get started, the 4th gear needs to be pulled off the input shaft. This is done with a standard gear puller. But what was not that standard, was the force required to get this actually off.

I ended up putting the puller’s screw in the vise, and used a long bar to rotate the gear around it for extra leverage. The deformation of the rather solid plate give a glimpse of the applied forces. Once this was finished, I was done for the week with any physical activities.

With the 4th gear off, the next step was to fill the gap between the 3rd and the 4th gear.

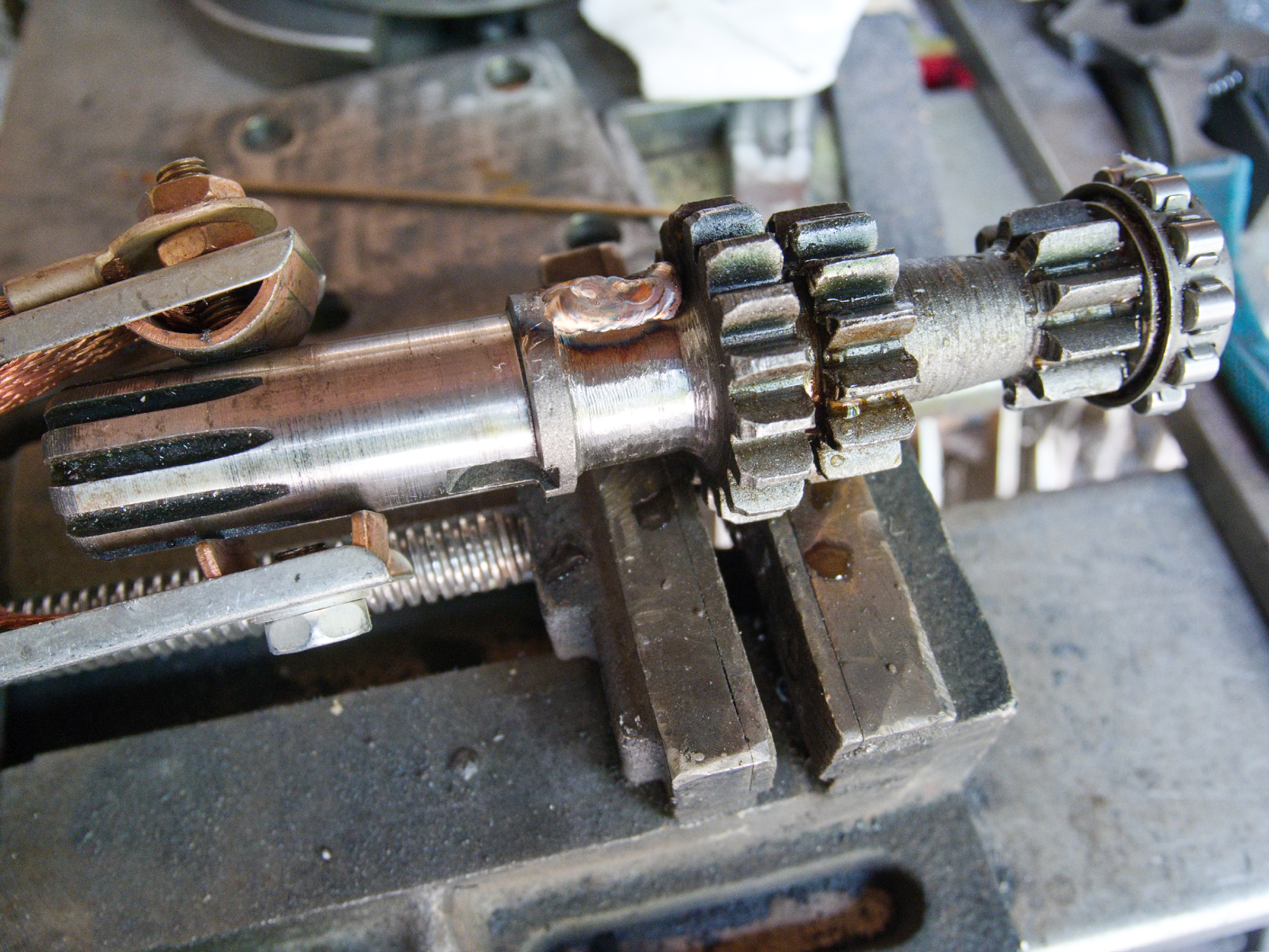

I used an older input shaft to try the brazing. Brazing involves applying just enough heat to melt the filler material without affecting the base material, allowing capillary action to bond the parts together.

I tried welding, but it put way too much heat in the part that it would change the metallurgical properties and the hardening of the part.

Using a TIG welder, brazing with Silicon-Bronze rods was actually quite easy.

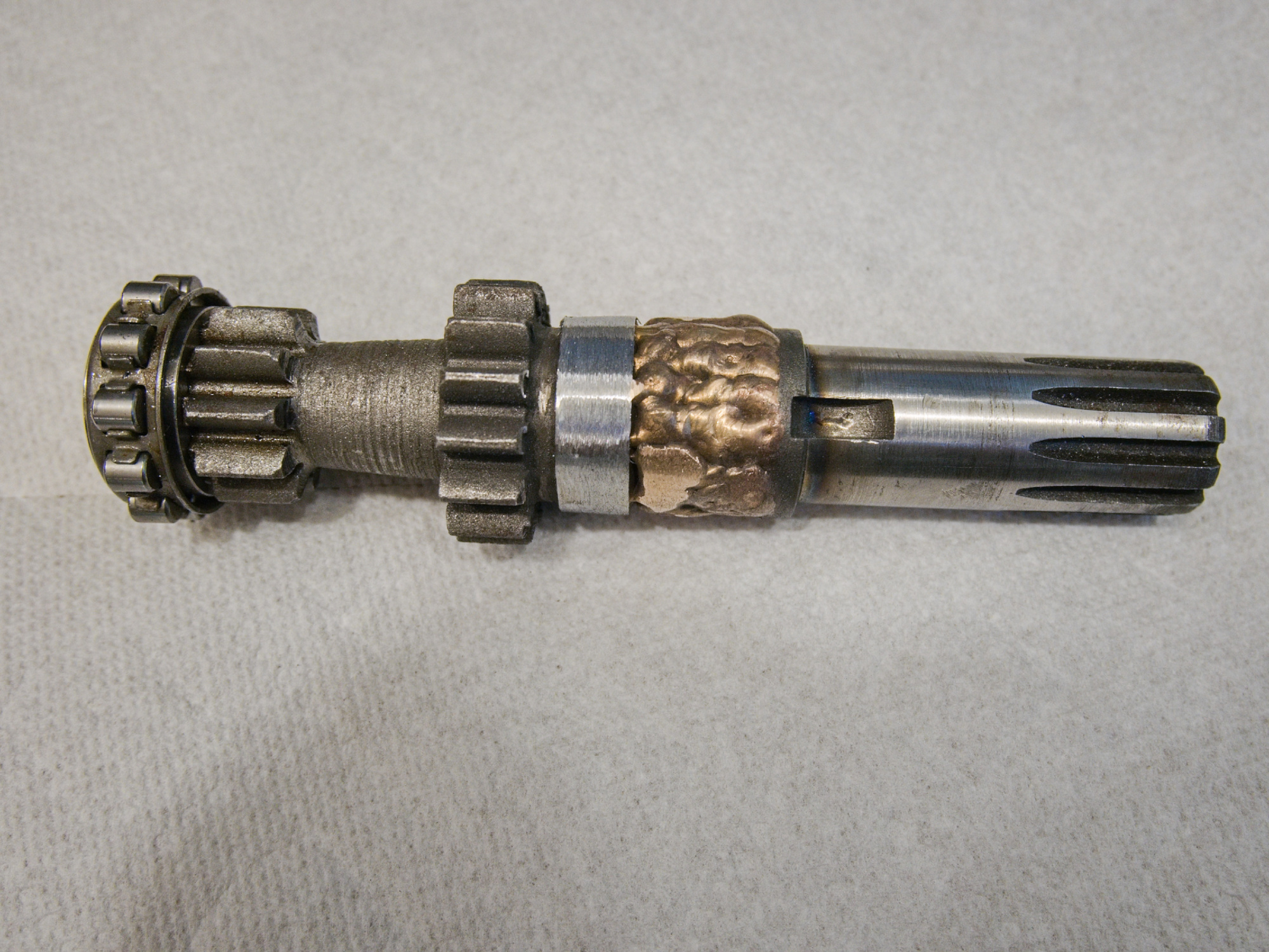

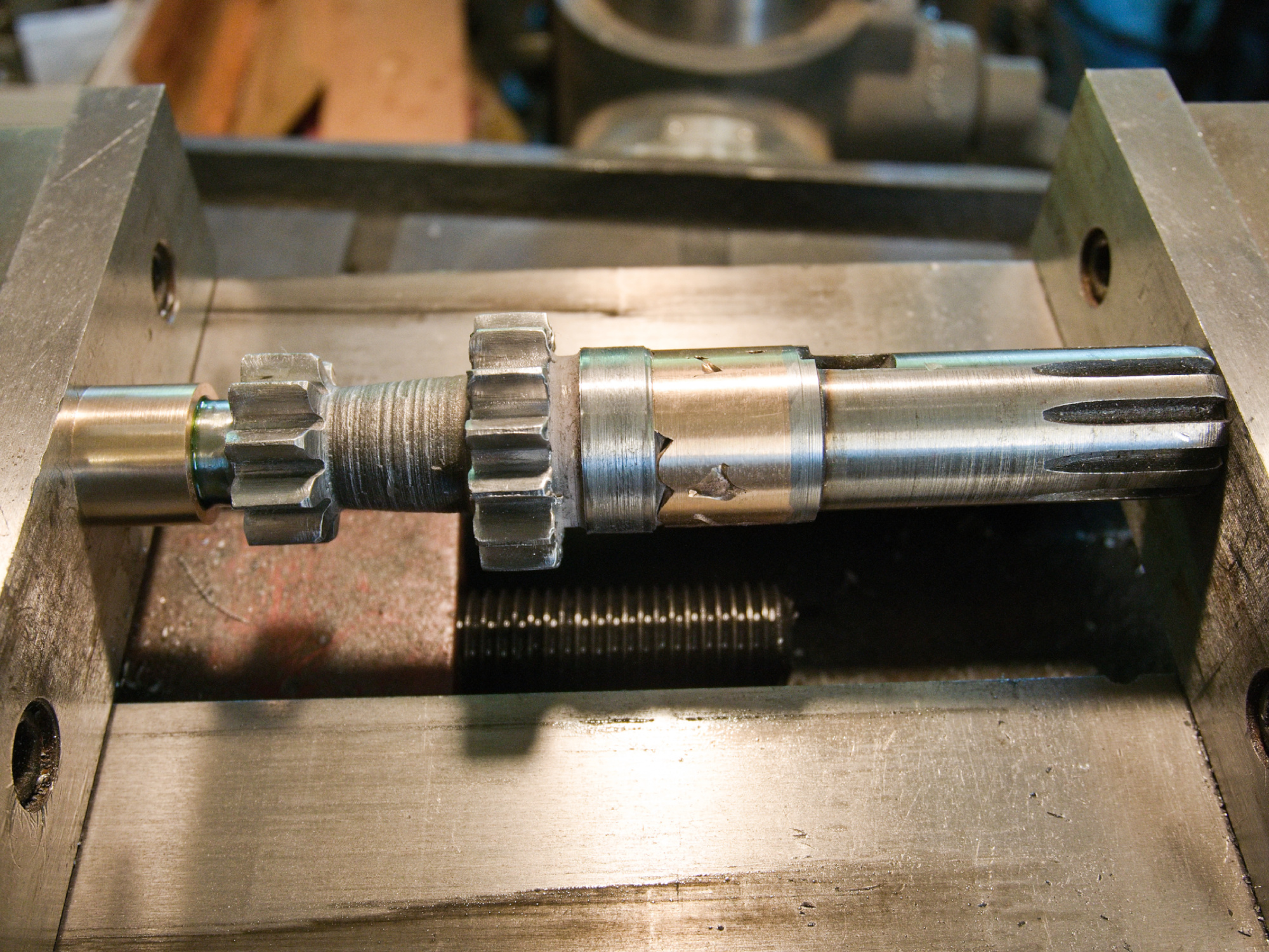

The input shaft used for the project.

I used water to keep the material temperature low.

The gap is all filled with Silicon-Bronze.

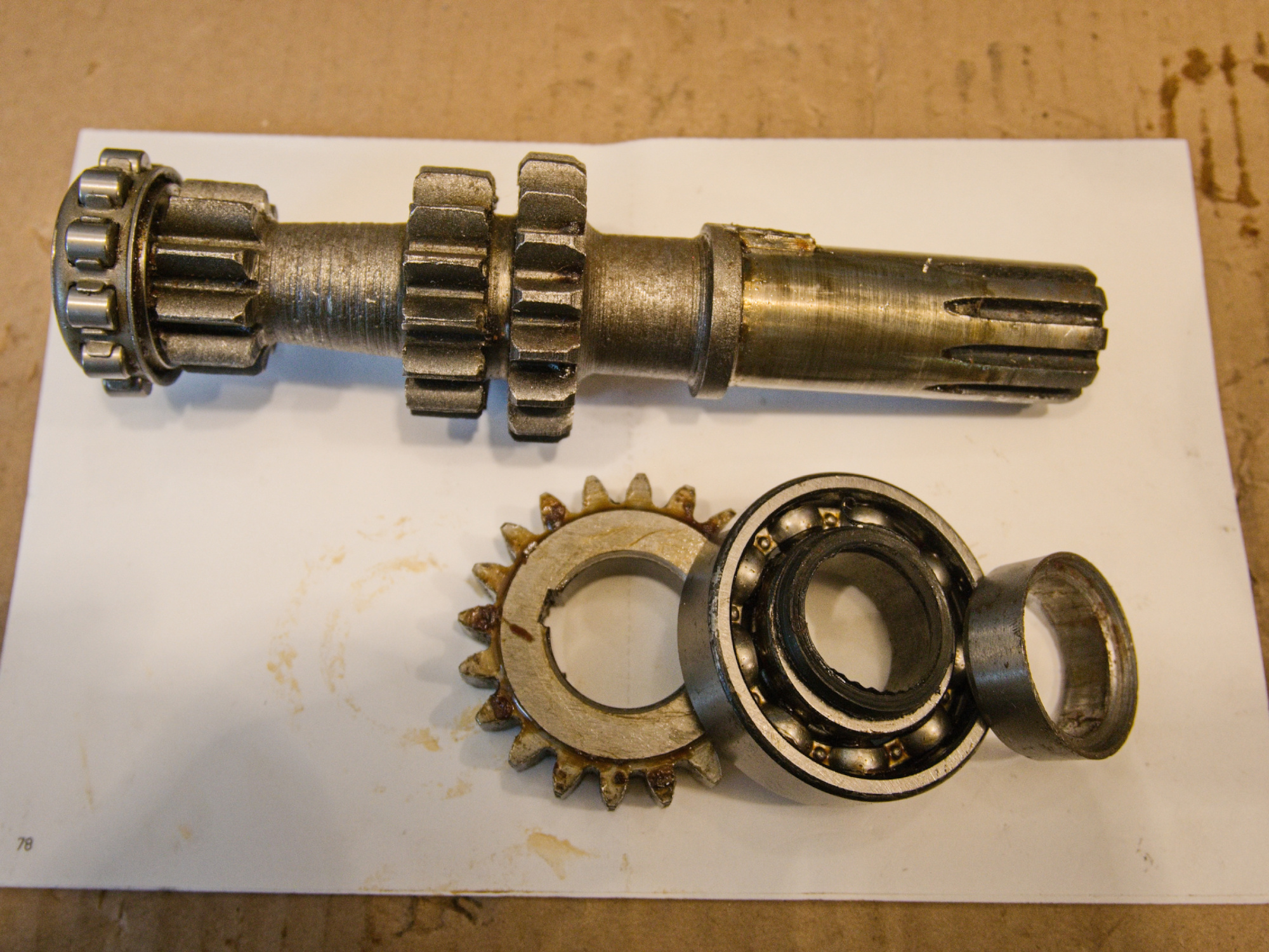

The 3rd gear was removed with a grinder.

The input shaft had a severe runout at the bearing. To fix this, I machined the front part and created a bronze bushing. The bushing for the bearing is pressed on in a machine vise and secured using Loctite 638 (green colored glue).

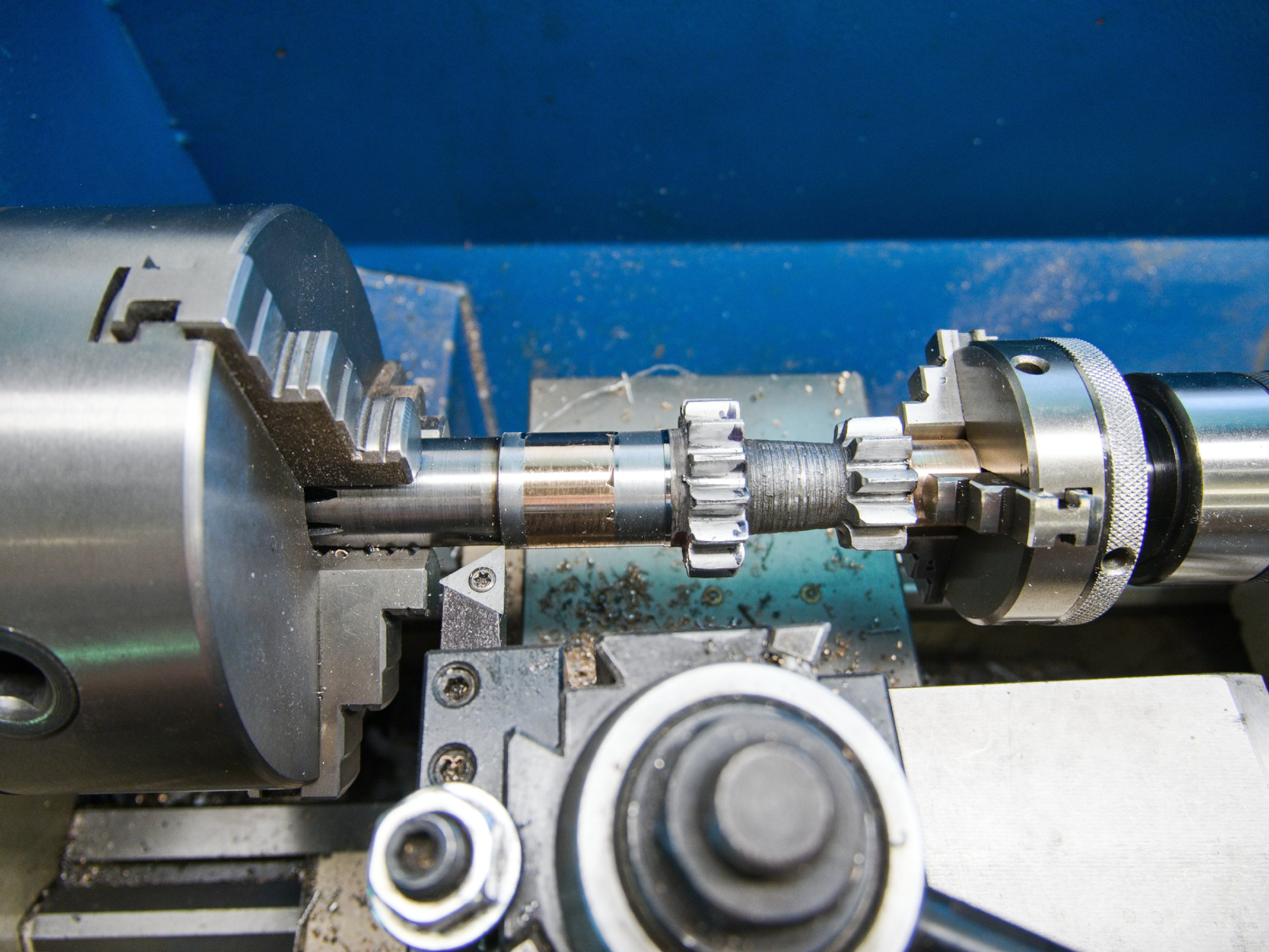

The shaft is machined to its final dimensions.

The old and the new input shaft.

The new 4th gear is secured with a key, while the 3rd gear locks into the 4th gear.

A standardized key is not wide enough for the slot and is padded with two small metal parts.