Oil Seals

01 May, 2023

As a common misconception the sealing surface is often polished for minimal wear, but for oil seals this has the opposite effect. The sealing surface needs to have a certain roughness to support an oil film. If the surface is too smooth, the oil film cannot be established and the seal runs dry, causing the parts to heat up and finally destroy the seal.

If on the other side the roughness is too large, the seal gets worn out quickly, resulting in the same fate.

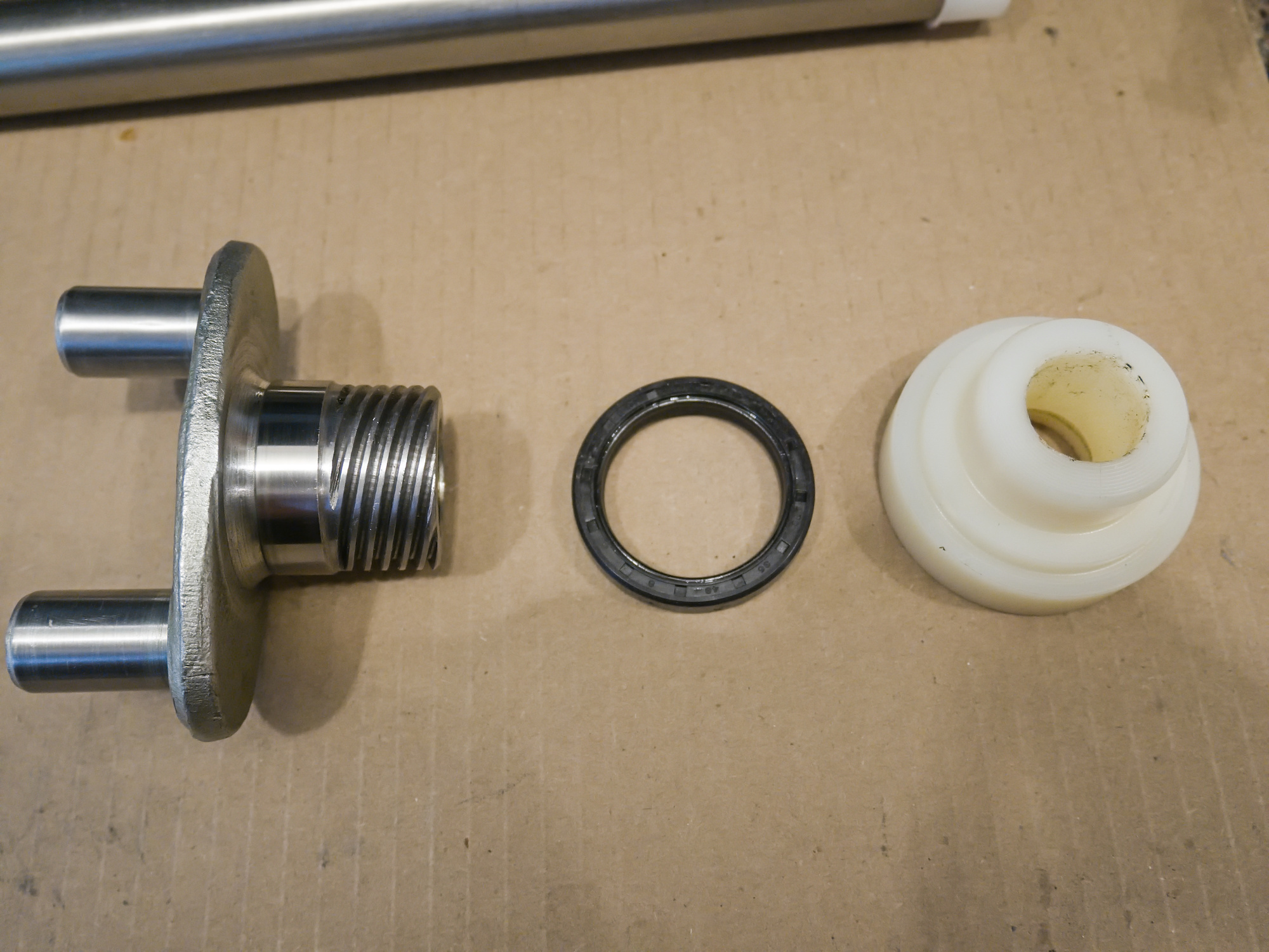

And this is what happend to my gearbox seal. For quite some time the coupler on the gearbox side was hot even after a short drive. The diameter of the sealing surface of the coupler is 36.5mm and the oil seal is TC36x48x8. This tight fit also contributed, but the sealing surface apparently was indeed too smooth for the seal when the sealing surface was done with 400 grit sandpaper.

The perfect roughness is Ra 0,2-0,8.

But how to get to this?

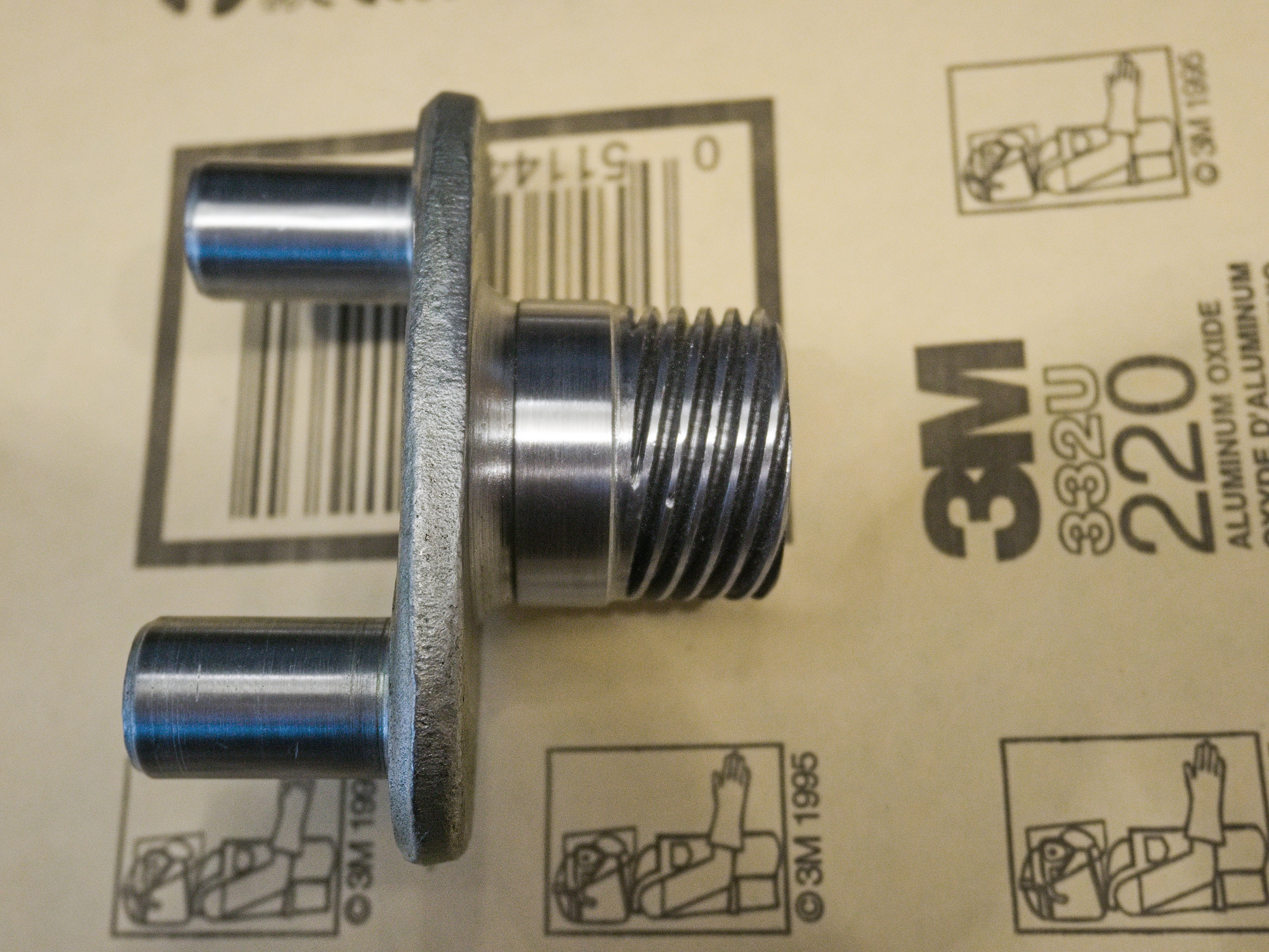

A 220 grit sandpaper gets to about a roughness of Ra 0,5 on metal. A few passes with 220 grit sandpaper around the sealing surface resulted in this, which still felt very smooth.

And with a new TC37x48x7, the seal is not too tight anymore (37mm instead of 36mm).

Back to service!